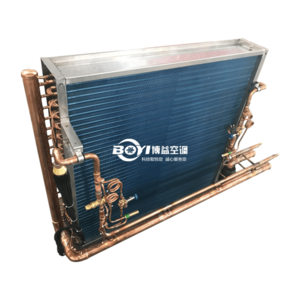

OEM/ODM Copper Tube Aluminum Fin Evaporator

- Model

- BY-ZFQ

Item specifics

- Core Component

- Finned tube heat exchangers

- Tube Diameter

- 7mm, 9.52mm, 12.7mm, 15.88mm

- Casing Material

- Galvanized Steel, Aluminium, Stainless Steel

- Tube Material

- copper, stainless steel

- Fin Material

- aluminum, copper, stainless steel

Review

Description

Definition:

A copper tube aluminum fin evaporator is a highly efficient heat exchanger widely used in refrigeration and air conditioning systems. It consists of copper tubes (for excellent thermal conductivity and corrosion resistance) mechanically bonded or hydraulically expanded into aluminum fins (which provide a large surface area for enhanced heat dissipation).

How They Work:

1. Refrigerant Flow: Low-pressure liquid refrigerant enters the coil via an expansion valve, which regulates the flow.

2. Heat Absorption: As warm air passes over the coils, the refrigerant absorbs heat, causing it to evaporate into a gas.

3. Cool Air Circulation: The now-cooled air is blown into the living space (in ACs) or cools the refrigerator compartment.

4. Cycle Continuation: The gaseous refrigerant travels to the compressor to restart the cycle.

Key Features:

1. High heat transfer efficiency due to copper’s thermal properties and aluminum’s lightweight, extended surface.

2. Corrosion-resistant (copper tubes withstand refrigerants, while aluminum fins are often coated for protection).

3. Compact and lightweight, ideal for HVAC/R applications.

4. Cost-effective balance between performance and material costs.

Applications:

1. Air conditioners (indoor/outdoor units).

2. Refrigerators & chillers.

3. Heat pumps and dehumidifiers.

Maintenance & Common Issues:

1. Dirt/Dust Buildup: Reduces efficiency; clean coils annually with a soft brush or coil cleaner.

2. Ice Formation: Caused by low refrigerant, poor airflow, or faulty components. Address promptly to prevent damage.

3. Refrigerant Leaks: Lead to poor cooling; require professional repair.

4. Bent Fins: Restrict airflow; gently straighten with a fin comb.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us