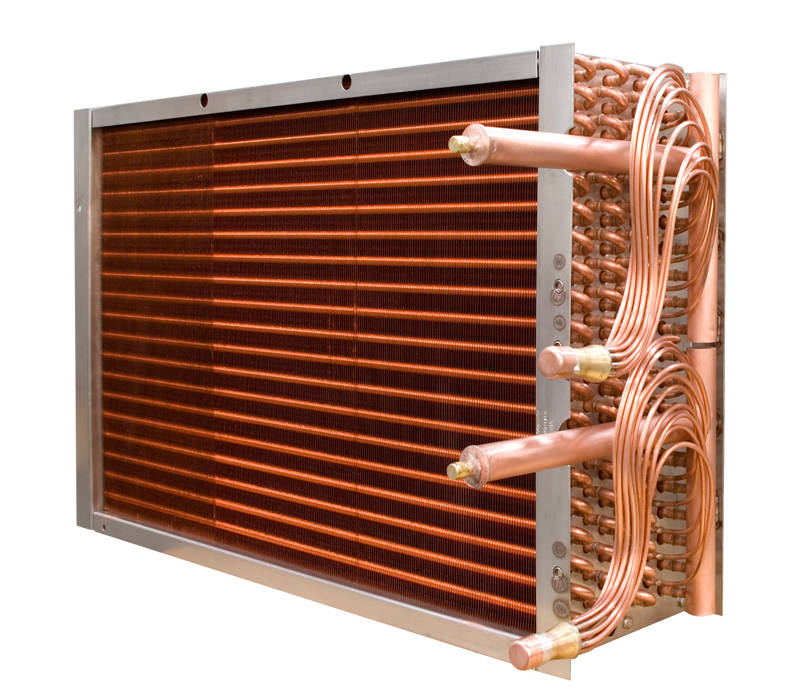

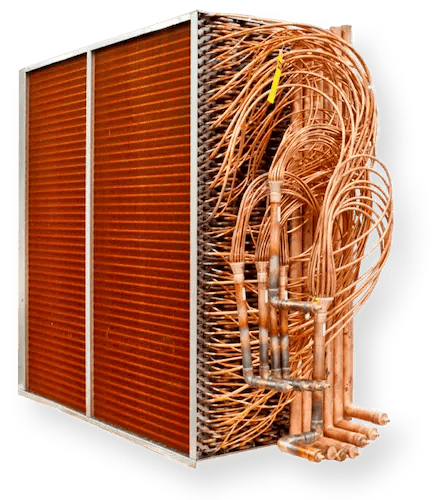

Different Size Evaporator Coil with Copper Tubes Aluminum Fins

- Model

- BY-ZFQ

Item specifics

- Core Component

- Finned tube heat exchangers

- Tube Diameter

- 7mm, 9.52mm, 12.7mm, 15.88mm

- Casing Material

- Galvanized Steel, Aluminium, Stainless Steel

- Tube Material

- copper, stainless steel

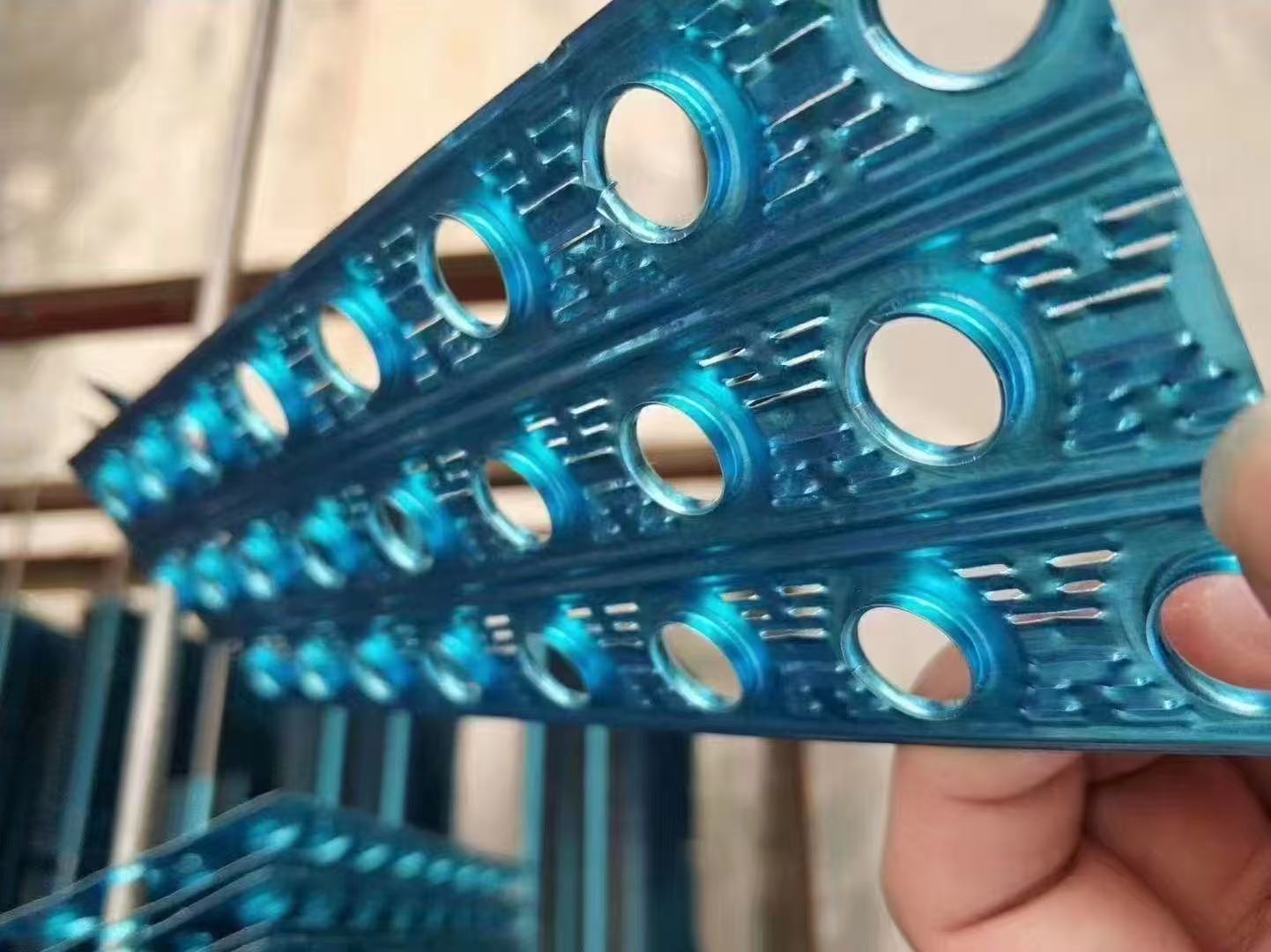

- Fin Material

- aluminum, copper, stainless steel

Review

Description

Definition:

We're a coil manufacturer and heat exchangers manufacturer and among our specialties are evaporator coils to suit any needs. Evaporator coils are a crucial part of any refrigeration system, which is why every evaporator coils we build each year is fully tested to ensure it meets your standards.

In a heat pump system, the operation detailed above is reversed with the evaporator coil expelling the heat into the building.

How They Work:

1. Refrigerant Flow: Low-pressure liquid refrigerant enters the coil via an expansion valve, which regulates the flow.

2. Heat Absorption: As warm air passes over the coils, the refrigerant absorbs heat, causing it to evaporate into a gas.

3. Cool Air Circulation: The now-cooled air is blown into the living space (in ACs) or cools the refrigerator compartment.

4. Cycle Continuation: The gaseous refrigerant travels to the compressor to restart the cycle.

Materials for Construction:

1. Aluminum fin

2. Hydrophilic pre-coated aluminum fin

3. Copper tube and fin

4. 304/316 Stainless Steel

5. Epoxy resin coatings

Refrigerant Experience:

1. Pure refrigerants such as R134a, R32 and R1234ze.

2. Refrigerant mixtures including R410A, R407C, R438A, R-454B, and R452A.

3. Supercritical refrigerant CO2.

4. Natural refrigerants such as Propane, Isobutane and Ammonia.

Maintenance & Common Issues:

1. Dirt/Dust Buildup: Reduces efficiency; clean coils annually with a soft brush or coil cleaner.

2. Ice Formation: Caused by low refrigerant, poor airflow, or faulty components. Address promptly to prevent damage.

3. Refrigerant Leaks: Lead to poor cooling; require professional repair.

4. Bent Fins: Restrict airflow; gently straighten with a fin comb.

Conclusion:

Our evaporator coils are used in several industries, including gas compression, HVAC, military, transit cooling, refrigerated display cases, data center electronics cooling, and ground support. No matter what your need, we can custom design an evaporator coil for you. Get started with BOYI Coils as your HVAC coil manufacturer today!

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us