Provide customized dry cooler solutions for AI liquid-cooled data centers and mining farms

- Model

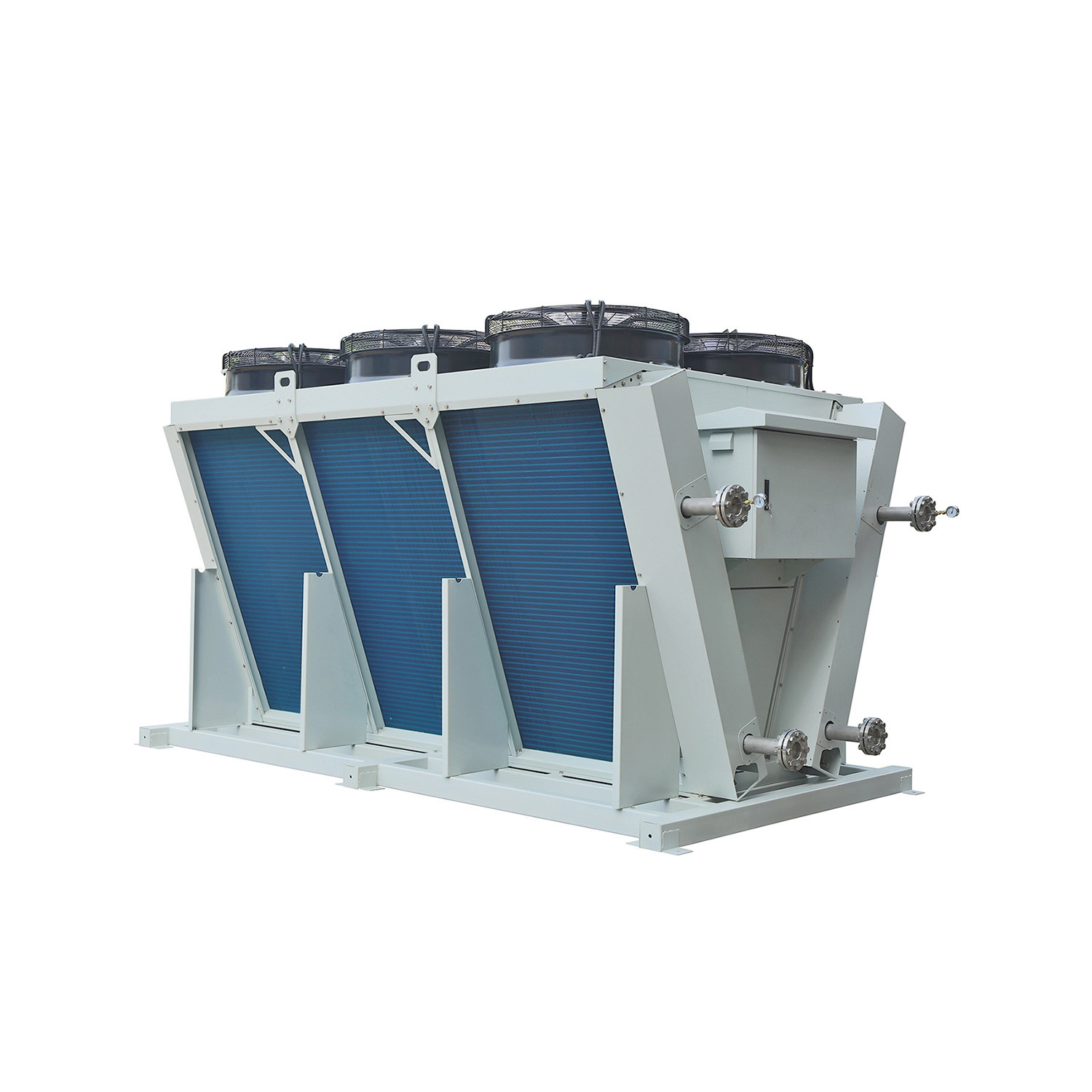

- BY-V-GLQ

Item specifics

- Core Component

- Finned Tube Heat Exchangers

- Tube Diameter

- 7mm, 9.52mm, 12.7mm, 15.88mm

- Casing Material

- Galvanized Steel, Aluminium, Stainless Steel

- Tube Material

- copper, stainless steel

- Fin Material

- aluminum, copper, stainless steel

Review

Description

V-Type Dry Cooler Key Features:

1. V-Type design for easy installation and space-saving.

2. Efficient heat dissipation to prevent equipment overheating.

3. Specifically designed for industrial cooling systems in data centers and mines.

4. Reliable and durable construction for long-lasting performance.

Background:

The customized cooling solution provided by BOYI DRY COOLER for AI liquid-cooled data centers and mining farms integrates dry coolers with auxiliary humidification/spray systems to achieve efficient heat dissipation and energy-saving goals. Below is the recommended solution and a detailed analysis of its advantages, based on industry technology trends and practical case studies.

Recommended core solutions for dry coolers:

1. High-efficiency dry cooler:

1.1 Technical Features: Integrates evaporative cooling technology with modular design, supports year-round operation, adapts to extreme environments (-40℃ to 45℃), single-unit capacity ranging from 100kW to 2000kW, ultra-low water consumption (WUE as low as 0~0.3), and heat exchange efficiency ≥20%.

1.2 Application scenarios: Suitable for water-scarce regions, high-altitude areas, and high-heat/high-humidity environments, meeting the dual requirements of PUE and WUE compliance, particularly ideal for green data center construction in the East-West Computing Resource Transfer Project.

1.3 Auxiliary compatibility: Can be integrated with the wind-liquid co-sourcing system, allowing flexible switching between air cooling and liquid cooling modes, and supporting high-density cabinets (with a cooling demand of 200kW+ per cabinet).

2. Container-type dry cooler:

2.1 Innovative Design: Patented exterior with advanced heat exchange technology, reducing energy consumption and enhancing installation flexibility, ideal for integrated server chilled water supply to meet the high cooling demands of AI computing power.

2.2 Environmental Sustainability: Aligns with the dual-carbon strategy, reduces carbon emissions, and adapts to the full life cycle management of data centers.

Supplementary solution for auxiliary cooling technology:

1. Cooling pad system:

Functional Advantages: The wet curtain increases air contact area, enables precise relative humidity control, reduces pressure drop (0.2 inches of water column) and energy consumption (annual savings of approximately 67,500 kWh), while supporting wastewater-free circulation and silver ion antibacterial technology to enhance hygiene and safety.

Applicability: Customizable sizes to fit various scenarios such as air conditioning and air ducts, with easy maintenance, making it ideal for data centers requiring precise humidity control.

2. The spray evaporative cooling technology (e.g., the case of Ningsuan Data Center in Tibet):

Utilization of dry air energy: In low-humidity environments, heat is absorbed through spray evaporation, combined with waste heat recovery (34% efficiency), achieving a PUE as low as 1.08, and enabling cross-industry energy synergy such as agricultural heating.

Regional Adaptation: Suitable for high-altitude, low-temperature, and dry regions (e.g., Lhasa), maximizing the use of natural cooling sources to reduce air conditioning energy consumption.

Summary of the core advantages of dry coolers:

1. Energy-saving and eco-friendly:

1.1 Significantly reduce water usage (WUE ≤ 0.3) and energy consumption (PUE ≤ 1.2), aligning with the national dual-carbon strategic goals.1.2 The design of "shared source for wind and liquid" reduces thermal pollution, supports waste heat recovery (e.g., the Tibet case), and improves comprehensive energy utilization efficiency.

2. Environmental adaptability:

Covering an extreme temperature range from -40°C to 45°C, it adapts to complex geographical conditions such as high altitude and water scarcity, addressing the failure issues of traditional cooling systems in high-heat, high-humidity, or low-temperature environments.

3. Flexibility and modularity:

3.1 Modular design supports rapid deployment and customizable configuration, meeting the needs of data centers of various scales and densities (such as single-cabinet 200kW+ scenarios).

3.2 It can be seamlessly integrated with other cooling technologies (such as liquid cooling and spray cooling) to form a hybrid cooling solution, enhancing system redundancy and reliability.

4. Optimization of long-term operational costs:

Low maintenance requirements and a long-life design minimize downtime and repair costs. Combined with AI algorithms (such as Dell's intelligent cooling solution) to enable predictive maintenance, further reducing operational risks.

Industry Application Case Studies:

1. Tibet Ningsuan Data Center: By utilizing dry air energy + spray evaporative cooling + waste heat recovery, it achieves a PUE ≤1.08, with the waste heat being used for heating in aquaculture, advancing the zero-carbon goal.

2. The batch delivery of BOYI DRY COOLER: Products with specifications exceeding 100MW have been deployed in intelligent computing centers, validating efficient delivery and operational stability in high-density scenarios.

3. Dell Intelligent Cooling Solution: Combining cold plate and immersion liquid cooling with air-cooled technology, supporting PUE as low as 1.02, adaptable for both new and existing data center upgrades.

Recommended solution combination:

1. Basic Solution: Dry cooler (such as BOYI DRY COOLER) as the main component, paired with modular cooling pads, suitable for conventional humidity control requirements.

2. Advanced Solution: Dry Cooler + Spray Evaporation System, suitable for arid or high-altitude regions, maximizing the utilization of natural cooling sources.

3. High-density scenario: Dry coolers and liquid cooling technology (such as air-liquid co-source architecture) work in synergy to meet heat dissipation demands of 200kW+ per rack.

Conclusion:

Through the above solution, the BoYi DRY COOLER can provide an efficient, flexible, and sustainable dry cooler cooling solution for AI liquid-cooled data centers and mining farms, meeting diverse high-computing demands and driving the industry's green transformation.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us