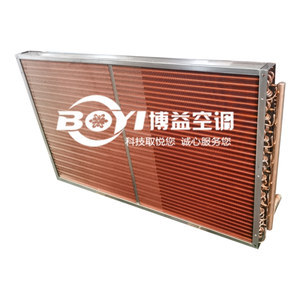

Air Conditioning Condenser Coil with Copper Tube Aluminum Fin

- Model

- BY-LNQ

Item specifics

- Core Component

- Finned Tube Heat Exchanger

- Tube Diameter

- 7mm, 9.52mm, 12.7mm, 15.88mm

- Casing Material

- Galvanized Sheet, Aluminium, Stainless Steel

- Tube Material

- Copper, Stainless Steel

- Fin Material

- Aluminum, Copper, Stainless Steel

Review

Description

Air Conditioning Condenser Coil with Copper Tube Aluminum Fin

A heat exchanger is an energy-saving device that transfers heat between materials at two or more fluids at different temperatures. It transfers heat from a higher temperature fluid to a lower temperature fluid, allowing the fluid temperature to reach the flow. Specified indicators to meet the needs of process conditions, but also one of the main equipment to improve energy efficiency.

Application

Mainly concentrated in the fields of petroleum, chemical, metallurgy, electric power, shipbuilding, central heating, refrigeration and air conditioning, machinery, food, pharmaceuticals, etc.

Our factory currently focuses on large heat exchangers for various industry.

Materials

1. Aluminum fin

2. Hydrophilic pre-coated aluminum fin

3. Copper tube and fin

4. 304/316 Stainless Steel

5. Epoxy resin coatings

Refrigerant Experience

1. Pure refrigerants such as R134a, R32 and R1234ze.

2. Refrigerant mixtures including R410A, R407C, R438A, R-454B, and R452A.

3. Supercritical refrigerant CO2.

4. Natural refrigerants such as Propane, Isobutane and Ammonia.

Maintenance & Common Issues

1. Dirt/Dust Buildup: Reduces efficiency; clean coils annually with a soft brush or coil cleaner.

2. Ice Formation: Caused by low refrigerant, poor airflow, or faulty components. Address promptly to prevent damage.

3. Refrigerant Leaks: Lead to poor cooling; require professional repair.

4. Bent Fins: Restrict airflow; gently straighten with a fin comb.

Conclusion

Our condenser coils are used in several industries, including gas compression, HVAC, military, transit cooling, refrigerated display cases, data center & electronics cooling, and ground support.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us