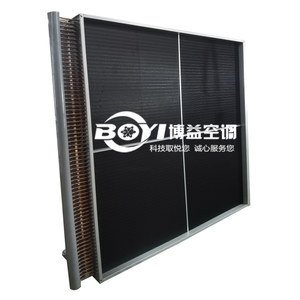

Custom Chilled Water Coils with different materials

- Model

- BY-CWC

Item specifics

- Core Component

- Finned tube heat exchangers

- Tube Diameter

- 7mm, 9.52mm, 12.7mm, 15.88mm

- Casing Material

- Galvanized Steel, Aluminium, Stainless Steel

- Tube Material

- copper, stainless steel

- Fin Material

- aluminum, copper, stainless steel

Review

Description

Definition:

Chilled water coils are heat exchange components used in HVAC systems to transfer heat between air and chilled water. They are commonly found in air handlers, fan coil units, and other air-conditioning systems.

How Chilled Water Coils Work:

1. Heat Transfer: Chilled water (typically at 40–50°F) flows through the coil’s tubes, while warm air passes over the fins.

2. Cooling Process: The warm air loses heat to the cold coil, cooling and dehumidifying before being distributed into the space.

3. Return to Chiller: The now-warmed water returns to the chiller to be re-cooled.

Materials:

1. Aluminum fin

2. Hydrophilic pre-coated aluminum fin

3. Copper tube and fin

4. 304/316 Stainless Steel tube and fin

5. Epoxy resin coatings

Maintenance Considerations:

1. Air Filters: Prevent dust buildup on fins.

2. Coil Cleaning: Regular cleaning to maintain efficiency.

3. Water Treatment: Prevents scaling/corrosion in tubes.

4. Freeze Protection: In cold climates, coils must be drained or glycol-mixed to prevent freezing.

Conclusion:

Chilled Water Coils are widely used in Air Handling Units (AHUs), Fan Coil Units (FCUs), Dedicated Outdoor Air Systems (DOAS), Data Center Cooling, Commercial & Industrial HVAC Systems due to their reliability and energy efficiency. No matter what your need, we can custom design an Chilled Water Coils for you. Get started with BOYI Coils as your HVAC coils manufacturer today!

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us