The Ultimate Guide to Dry Cooler: Revolutionizing Industrial Cooling with Air-Cooled Heat Exchanger

- Share

- publisher

- Sam Chang

- Issue Time

- Oct 21,2025

Summary

Discover the power of dry coolers and air-cooled heat exchangers. This comprehensive guide explores their working principles, core components, significant benefits like water conservation and reduced costs, and diverse industrial applications. Learn why this sustainable technology is a superior choice for modern cooling needs compared to traditional methods.

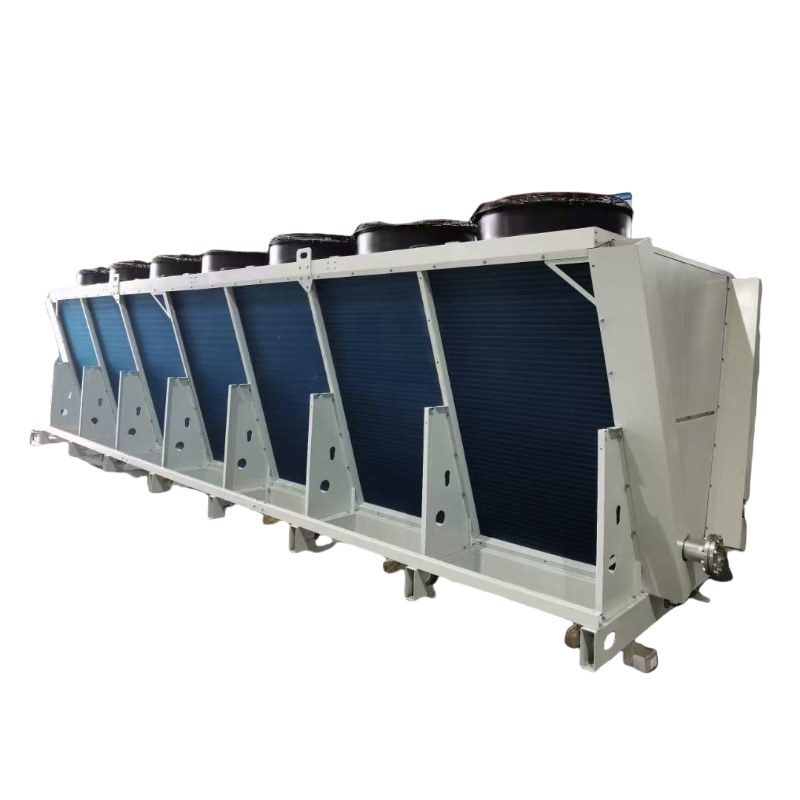

In a world where industrial efficiency and environmental sustainability are paramount, managing heat effectively has become a critical challenge. Air-Cooled Heat Exchangers (ACHEs), commonly known as dry coolers, offer a powerful, efficient, and eco-friendly solution. By using ambient air to dissipate heat, these systems provide a compelling alternative to traditional water-based cooling methods, marking a significant step forward in industrial process management.

What is a Dry Cooler (Air-Cooled Heat Exchanger)?

A dry cooler is a heat exchange device that uses air to cool a process fluid, which is typically water or a water-glycol mixture. The entire process operates on the principle of sensible heat rejection, where the heat from the fluid is transferred to the air without any evaporation. This closed-loop system means the process fluid never comes into direct contact with the air, preventing contamination and water loss. This technology is especially vital in regions with water scarcity or strict environmental regulations.

How Do Dry Coolers Work? The Core Principle

The operation of a dry cooler is elegantly simple yet highly effective. It revolves around convection and conduction to transfer thermal energy.

- Fluid Circulation: Hot fluid from an industrial process is pumped through a network of tubes within the dry cooler.

- Airflow Generation: Large axial fans draw in ambient air from the surrounding environment and force it to flow across the external surfaces of the tubes.

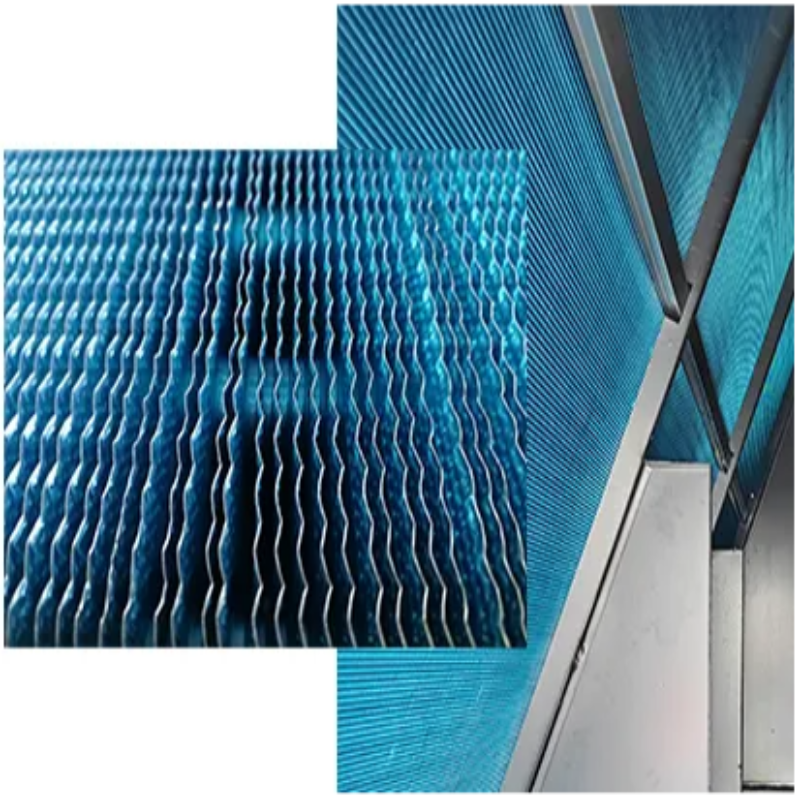

- Heat Transfer: The tubes are covered in fins, usually made of aluminum, which dramatically increase the surface area available for heat transfer. The heat from the fluid conducts through the tube walls and fins.

- Heat Dissipation: As the cooler ambient air passes over the fins, it absorbs the heat, raising the air temperature. This warmed air is then expelled into the atmosphere.

- Recirculation: The now-cooled fluid exits the dry cooler and is pumped back to the industrial process to absorb more heat, completing the cycle.

Key Components of a Dry Cooler

A dry cooler is constructed from several essential parts that work in unison to achieve efficient cooling:

- Finned Tube Bundle: This is the heart of the system. It consists of tubes (often carbon steel or stainless steel) that carry the process fluid, and attached fins (usually aluminum) that maximize the heat exchange surface. The type of fin—such as L-fin, G-fin (embedded), or extruded—is chosen based on the application's temperature and environmental conditions.

- Fans & Motors: Axial fans are responsible for moving large volumes of air across the tube bundle. They are driven by electric motors, with modern designs often incorporating variable-speed drives (VFDs) to optimize energy consumption based on cooling demand.

- Frame and Structure: A robust, weatherproof frame made of galvanized or painted steel provides structural integrity and protects the internal components from the elements.

- Plenum Chamber: This enclosure directs the airflow evenly across the entire tube bundle, ensuring consistent and efficient cooling performance.

- Headers: These are box-like chambers at each end of the tube bundle that distribute the process fluid into the tubes and collect it after it has been cooled.

The Major Advantages of Choosing a Dry Cooler

Opting for a dry cooling system offers numerous benefits that make it a superior choice for many industries.

- Significant Water Conservation: Since dry coolers do not rely on evaporation, they consume no water. This eliminates costs associated with water purchase, treatment, and disposal, making them an ideal solution for arid regions and environmentally conscious operations.

- Lower Operating and Maintenance Costs: The simplicity of the design, with fewer moving parts and no need for water-related upkeep (like chemical treatment to prevent scaling and biological growth), results in significantly lower maintenance requirements and reduced operational expenses.

- Environmental Sustainability: By eliminating water consumption, dry coolers prevent thermal and chemical pollution of natural water bodies. Their enhanced energy efficiency also contributes to a smaller carbon footprint.

- Flexibility and Simple Installation: Dry coolers are relatively easy to install and can be located flexibly, often on rooftops, freeing up valuable ground space. They do not require the complex plumbing and basin infrastructure of cooling towers.

- Process Purity: The closed-loop design ensures that the process fluid remains clean and uncontaminated, which is critical in sensitive applications like food and beverage or pharmaceutical manufacturing.

Dry Cooler vs. Wet Cooling Tower: A Comparative Analysis

While both systems reject heat, their methods and impacts differ substantially. Understanding these differences is key to making the right choice for your application.

| Feature | Dry Cooler (Air-Cooled Heat Exchanger) | Wet Cooling Tower |

|---|---|---|

| Cooling Medium | Ambient Air | Water (Evaporation) |

| Water Consumption | None | High (due to evaporation, drift, and blowdown) |

| Cooling Limit | Limited by ambient dry-bulb temperature | Can cool below ambient dry-bulb temperature |

| Maintenance | Low (no water treatment, scaling, or legionella risk) | High (requires chemical treatment, cleaning, and water management) |

| Installation | Simpler, more flexible | More complex, requires basin and extensive plumbing |

| Environmental Impact | Low (no water pollution) | Higher (water consumption, chemical discharge) |

| Fouling Risk | Low (closed loop) | High (open loop, prone to contamination) |

Common Industrial Applications

Dry coolers are incredibly versatile and are deployed across a wide range of sectors for reliable temperature regulation.

- Power Generation: Used for cooling turbine lubricants, jacket water, and in steam condensation cycles, especially in plants focused on sustainability.

- Oil & Gas: Essential for cooling crude oil, natural gas, and various refined products in upstream, midstream, and downstream operations.

- HVAC & Refrigeration: Widely used for heat rejection in large-scale commercial air conditioning systems and industrial refrigeration, including cold storage and food processing.

- Data Centers: Provide efficient and reliable cooling for servers and IT equipment, helping to reduce the massive energy and water footprint of modern data centers.

- Chemical and Petrochemical Processing: Help regulate temperatures in numerous chemical production processes, ensuring safety and product consistency.

- Renewable Energy: Support cooling processes in geothermal, biomass, and solar thermal power generation facilities.

Main Types of Dry Coolers

Dry coolers come in several configurations to suit different spatial and performance requirements.

- Horizontal (Flat-Bed) Coolers: These have a horizontal tube bundle with fans positioned underneath (forced draft) or above (induced draft). They are often elevated to save ground space.

- V-Type Coolers: This design features two finned tube bundles arranged in a 'V' shape, which allows for a larger heat exchange surface area in a smaller footprint compared to horizontal models.

- -Adiabatic Coolers: These are hybrid systems that enhance performance in hot, dry climates. They pre-cool the incoming air by spraying a fine mist of water, which evaporates and lowers the air temperature before it passes over the main coil. This allows the system to cool the process fluid to a temperature below the ambient dry-bulb temperature, while still using significantly less water than a traditional cooling tower.

Forced Draft vs. Induced Draft Designs

The placement of the fans relative to the tube bundle defines two primary design types:

- Forced Draft: Fans are located beneath the tube bundle and push air through the fins. This design is more common, offers easier fan maintenance, and is more power-efficient as the fans handle cooler, denser air.

- Induced Draft: Fans are mounted on top of the tube bundle and pull air through the fins. This results in a more even air distribution and a higher exit velocity, reducing the chance of hot air recirculation. However, fan maintenance is more difficult, and the fans operate in the hot air stream, which can affect their longevity.

Maintenance Best Practices for Longevity

To ensure your dry cooler operates at peak efficiency and enjoys a long service life, a proactive maintenance schedule is essential.

- Regular Visual Inspection: Check for any signs of damage, corrosion, or vibration in the structure, fans, and motors.

- Keep Fins Clean: The finned surfaces are critical for heat transfer. Regularly remove any accumulated dust, pollen, leaves, or other debris using compressed air or a soft brush. For heavy fouling, low-pressure water washing may be necessary. Always clean in the direction of the airflow.

- Inspect Fans and Motors: Check fan blades for damage, ensure belts are properly tensioned (if applicable), and lubricate motor bearings according to the manufacturer's recommendations.

- Check for Leaks: Periodically inspect the tube bundles and headers for any signs of fluid leakage.

- Monitor Performance: Keep track of operating temperatures and pressures. A gradual increase in the fluid outlet temperature can indicate fouling or reduced fan performance.

The Future of Industrial Cooling

As industries worldwide continue to prioritize sustainability and operational efficiency, the role of air-cooled heat exchangers will only grow. Innovations in materials science are leading to fins and tubes with better thermal conductivity and corrosion resistance. Furthermore, the integration of IoT sensors and smart control systems allows for real-time performance monitoring and predictive maintenance, further reducing energy consumption and preventing downtime. The move towards water-free, low-maintenance cooling is not just a trend—it's the future of responsible industrial operations.