Adiabatic Fluid Cooler - Adiabatic V-Type

- Share

- publisher

- Sam Chang

- Issue Time

- Jul 29,2025

Summary

The Boyi Cooling Adiabatic V-Type is a premier solution for efficient heat rejection in modern cooling systems. This advanced design integrates dry and wet cooling to achieve substantial water and energy savings.

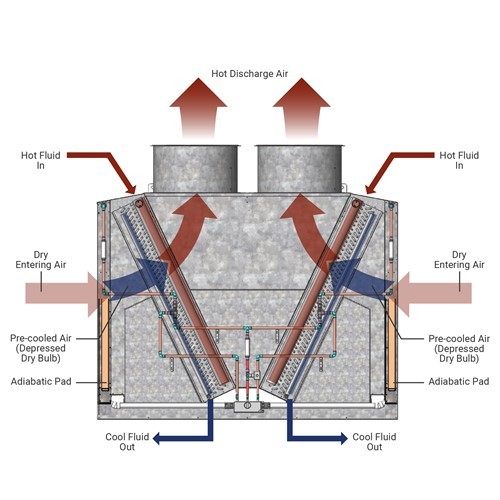

Adiabatic Fluid Cooler - Adiabatic V-Type

The Boyi Cooling Adiabatic V-Type seamlessly integrates dry and wet operation to deliver an energy-efficient and water-saving solution. This innovative technology includes a water recirculation system, advanced controls package, and adiabatic pads, enabling adaptive operation in response to outside environmental conditions. The adiabatic system is offered as an optional feature for Boyi Cooling Fluid Coolers, Air-Cooled Condensers, and CO2 Gas Coolers, providing enhanced performance across various applications.

1. Increased energy and water savings through Boyi recirculated water system design

2. No water treatment

3. Reduced maintenance

4. Energy efficient EC fan motor technology

5. Large capacity configurations available

6. Designed to fit your footprint

7. Compatible with all refrigerants

How does Adiabatic Cooling work in Industrial Refrigeration Systems

Adiabatic cooling in industrial refrigeration systems improves cooling efficiency by lowering the temperature of the air entering the heat exchanger coils. Wet media pads positioned before or around the heat exchanger coils cool the air by evaporating water from the pads. This temperature differential facilitates more effective heat transfer, which is essential for maintaining lower temperatures and achieving the desired cooling effect in various industrial applications, such as data center, mining farm, cold storage, food processing, and more.

Recirculated Water System

Exclusive Boyi design for water savings and energy efficiency, eliminating the need for water treatment. The Boyi Recirculated Water System provides superior efficiency compared to a once-through water distribution system that’s commonly used in other adiabatic cooling systems.

Adiabatic Pad System

Adiabatic Cooling Pads are wetted as air enters through the unit from the pull of the fans, resulting in higher cooling performance.

1. High quality, high cooling effectiveness adiabatic pads

2. Two adiabatic pad designs for either lowest water usage or lowest first cost

3. Designed for easy servicing and replacement

4. Complete unit controller for fan speed and water on/off functionality to maintain a specified leaving fluid/gas temperature

EC Fan Motor Technology

The Boyi Adiabatic Cooler uses EC fan motors as standard. EC fans are a complete fan/motor assembly which includes a highly engineered fan and bell mouth matched to an Electronically Commutated (EC) motor. EC fan motors provide several inherent advantages over traditional AC fans.

1. Built in variable fan speed control: Offers operational sequences and fan speed regulation in response to real-time heat loads and ambient environmental conditions, increasing energy efficiency.

2. Compliance with energy regulations: Many regions and industries have regulations that encourage or require the use of energy-efficient equipment. EC motors often meet or exceed these requirements, ensuring compliance.

3. Quiet Operation: EC fan motors operate with reduced noise levels, making them ideal for applications where noise control is important, such as in offices, residences, and commercial spaces.

4. Extended Lifespan: Due to their efficient operation and reduced wear and tear, EC motors typically have a longer lifespan compared to traditional AC motors, leading to lower maintenance and replacement costs.

Heat Exchanger Construction

1. Copper tube standard: Ø7, Ø9.52, Ø12.7, Ø15.88, tube thickness options to optimize heat transfer efficiency for the application.

2. Fin thickness: 0.105-0.25mm.

3. Fin material option: Aluminum, Copper, Stainless Steel, Epoxy Coated Aluminum.

4. Industrial casing: Galvanized Sheet, Aluminium, Stainless Steel.

Adiabatic Cooler Unit Size

1. Fan row: 1-2

2. Fan per row: 1-10