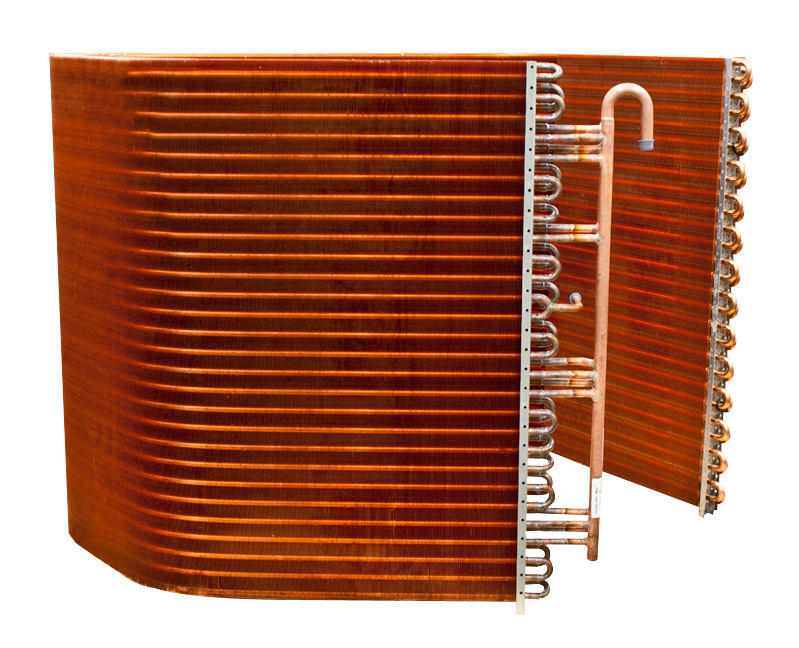

Custom Condenser Coils with different materials

- Model

- BY-LNQ

Item specifics

- Core Component

- Finned tube heat exchangers

- Tube Diameter

- 7mm, 9.52mm, 12.7mm, 15.88mm

- Casing Material

- Galvanized Steel, Aluminium, Stainless Steel

- Tube Material

- copper, stainless steel

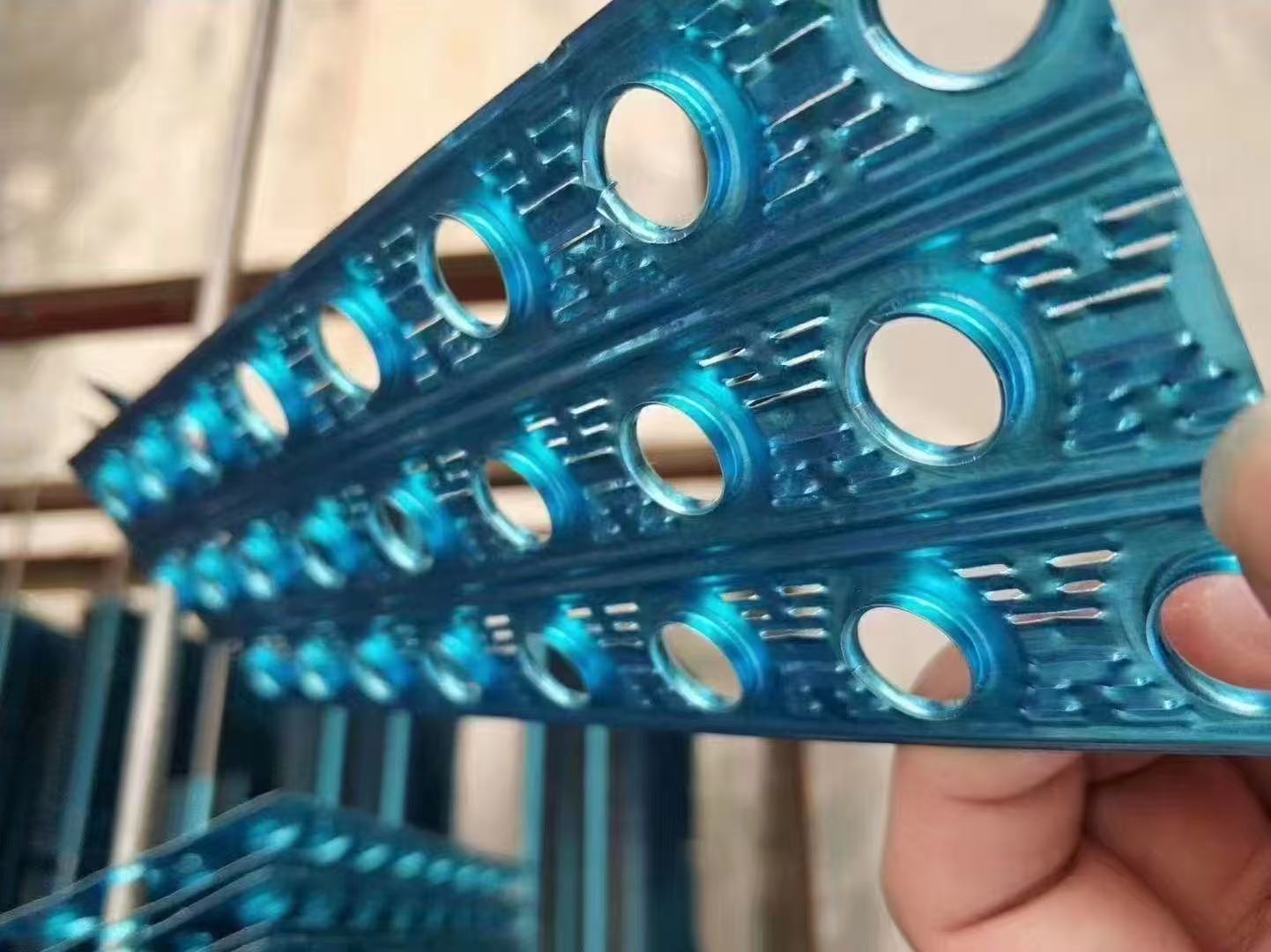

- Fin Material

- aluminum, copper, stainless steel

Review

Description

Definition:

A condenser coil is an essential component of any refrigerant system. Its primary functions are to remove heat from the refrigerant and support the conversion of the refrigerant back to a liquid state. Specifically, heat is removed as air passes over top of the coil while an integral or dedicated sub-cooling section directs the conversion of the refrigerant from a gas to a liquid. We’re condenser experts, with many years of experience designing and manufacturing.

Construction Options:

1. Interlaced, multi-circuit

2. Split Face

3. A-Frame

4. Mutli Row

Materials:

1. Aluminum fin

2. Hydrophilic pre-coated aluminum fin

3. Copper tube and fin

4. 304/316 Stainless Steel

5. Epoxy resin coatings

Refrigerant Experience:

1. Pure refrigerants such as R134a, R32 and R1234ze.

2. Refrigerant mixtures including R410A, R407C, R438A, R-454B, and R452A.

3. Supercritical refrigerant CO2.

4. Natural refrigerants such as Propane, Isobutane and Ammonia.

Maintenance & Common Issues:

1. Dirt/Dust Buildup: Reduces efficiency; clean coils annually with a soft brush or coil cleaner.

2. Ice Formation: Caused by low refrigerant, poor airflow, or faulty components. Address promptly to prevent damage.

3. Refrigerant Leaks: Lead to poor cooling; require professional repair.

4. Bent Fins: Restrict airflow; gently straighten with a fin comb.

Conclusion:

Our condenser coils are used in several industries, including gas compression, HVAC, military, transit cooling, refrigerated display cases, data center & electronics cooling, and ground support. No matter what your need, we can custom design an condenser coil for you. Get started with BOYI Coils as your HVAC coils manufacturer today!

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us