Corrugated fins, Louvered fins and black fins in finned tube heat exchanger

- Share

- publisher

- Sam Chang

- Issue Time

- May 20,2025

Summary

The thermal exchange technology finned tube heat exchangers three type fins: Corrugated fins, Louvered fins, Black fins.

What is a corrugated fin?

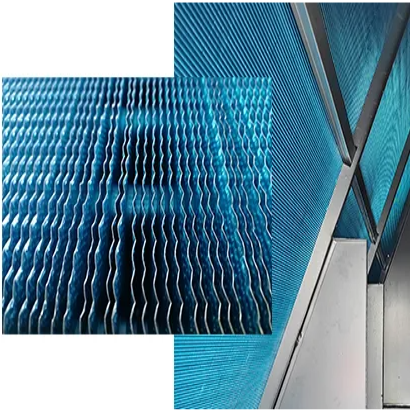

Corrugated fins, as the name suggests, feature a wavy shape. This design is not arbitrary but is based on in-depth research in fluid dynamics and heat transfer.

A certain waveform, such as a herringbone pattern, is pressed onto plain fins, causing the fluid to continuously change its flow direction within the curved channels. This alteration in flow pattern can effectively promote fluid turbulence, separation, and boundary layer disruption, thereby enhancing heat transfer efficiency.

What is a louvered fin?

Unlike corrugated fins, louvered fins are designed with a greater emphasis on heat exchange efficiency parallel to the airflow direction. Their structure typically features multiple elongated louvers, which not only enhance the bending strength of the fins, improving durability, but also cleverly reduce the gaps between fins, thereby lowering the risk of gas leakage.

The single-sided bonding structure of louvered fins allows the fluid to exchange heat more smoothly as it flows through the fins. When the fluid flows parallel to the direction of the fins, the louvered design guides the fluid to distribute more evenly across each channel, achieving more uniform and efficient heat exchange. This design not only improves heat transfer efficiency but also makes the fins more convenient and faster to manufacture and install.

Louvered fins are widely used in refrigeration equipment. For instance, in evaporators, louvered fins can significantly enhance heat exchange efficiency, allowing the refrigerant to more fully absorb heat from the air and thereby achieving rapid cooling.

What are the advantages of selecting black fins for finned tube heat exchangers?

1. Black fins have excellent corrosion resistance:

This feature benefits from the special coating technology applied to its surface. Traditional fin materials, such as pure aluminum foil, are lightweight and have good thermal conductivity, but they are prone to corrosion, especially in harsh environments like coastal or industrial areas, where they are more likely to develop "white powder" and "odors," compromising the air conditioner's performance and lifespan.

2. Black fins have excellent thermal conductivity:

Thermal conductivity is one of the key indicators for evaluating the performance of finned tube heat exchangers. The black fins, made of new materials such as carbon fiber and graphene, feature extremely high thermal conductivity, enabling rapid heat transfer and improving the cooling and heating efficiency of air conditioners.

3. The black fins also have excellent self-cleaning properties:

This feature primarily benefits from a specially treated highly hydrophilic coating on its surface. When the air conditioner is running, condensate forms a thin water film on the fin surface instead of water droplets. This water film can carry away dirt and impurities on the fins, reducing the growth of bacteria and mold, thereby maintaining the cleanliness and hygiene of the fins.

4. Why do black fins appear black?

This is primarily because the black fins utilize a carbon fiber and resin composite nano-coating that inherently has a black or dark-colored appearance. Additionally, the carbon elements and other additives in the coating can absorb and reflect light, giving the fin surface a more uniform and deeper black appearance.

Summary

In summary, the selection of black fins for air-conditioning finned tube heat exchangers is primarily based on their excellent corrosion resistance, outstanding thermal conductivity, and effective self-cleaning properties. These advantages not only enhance the overall performance and service life of the air conditioner but also provide users with a more comfortable, healthy, and energy-efficient experience.